From Brines to Minerals – IDTechEx Explores Lithium Extraction

Lithium exists naturally in various forms, mostly in brines and minerals found in hard rock. Traditionally, hard rock mining and evaporation ponds have been the primary methods for lithium extraction, but direct lithium extraction (DLE) forms examples of other up-and-coming techniques which IDTechEx explores in their latest report, “Direct Lithium Extraction 2025-2035: Technologies, Players, Markets and Forecasts”, which discusses these processes in connection to the lithium-ion battery market.

Products of lithium extraction and refining

Lithium sulfate and lithium chloride are the typical intermediate products of extraction processes. They are often refined to battery-grade lithium carbonate and lithium hydroxide, both used for the synthesis of lithium-ion battery cathodes, but for different battery chemistries due to their different properties. Lithium carbonate is the mainstream lithium product, and it has a higher melting point, lower reactivity, and a longer shelf life. It is commonly used for the synthesis of cathodes with low nickel or nickel-free formulations, such as lithium iron phosphate (LFP). Additionally, it is an intermediate product to lithium hydroxide. Lithium hydroxide has a lower melting point and higher reactivity and is often used for the synthesis of higher energy-density nickel-rich cathodes. This is because the synthesis of high nickel cathodes requires a lower reaction temperature.

Achieving a high nickel content within a layered oxide Li-ion cathode, such as nickel-manganese-cobalt (NMC) or nickel-cobalt-aluminium (NCA), is a goal for the battery industry as it provides a high energy density, which is key in dictating the driving range of an electric vehicle. Though lithium is also used for lubricants and in the glass and ceramics sector, IDTechEx's report shows non-battery demands for lithium to be decreasing.

Evaporation pond and DLE methods for lithium extraction from brines

Brine evaporation is a traditional method of lithium extraction which uses evaporation ponds. Solar evaporation can take several months and up to two years, and large areas of space are required for pond facilities. While brine evaporation has low carbon emissions due to the use of renewable solar energy, the lithium yield is typically around 40-60% – not as high as other methods of competition.

Adsorption DLE is the only commercially proven type of DLE method. The method uses adsorbents to selectively extract and capture lithium, which is then unloaded from the solid material by being washed down with water. The washed water contains a higher concentration of lithium (typically existing as lithium chloride) and a lower impurity content than that of raw brine and can be purified further to be converted into either lithium carbonate or hydroxide. Brine DLE methods can be used in conjunction with evaporation ponds, but the current wave of DLE technologies aims to eradicate pond usage.

A lithium-rich stream is produced when brine flows through an extraction unit, which is typically further processed through various membranes to remove impurities and water, allowing further lithium concentration. DLE methods can produce a lithium yield of around 80-95% in a few hours to days.

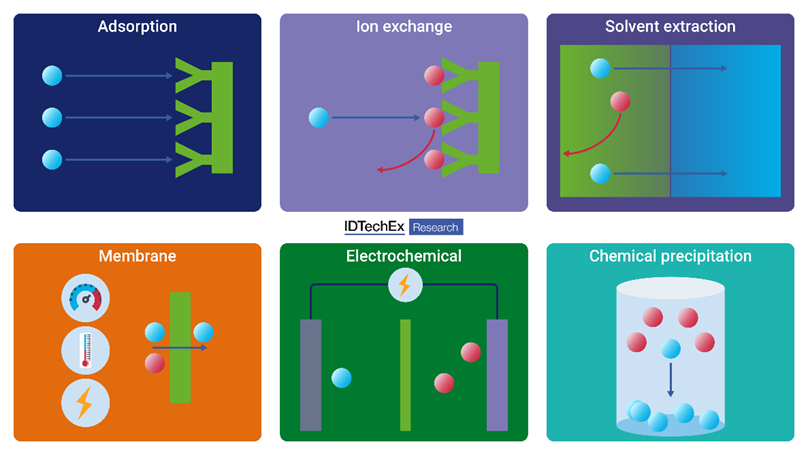

Six classes of lithium extraction and recovery technologies covered in the IDTechEx report, “Direct Lithium Extraction 2025-2035: Technologies, Players, Markets and Forecasts”. Source: IDTechEx.

Hard rock mining and sedimentary lithium extractions

Hard rock mining uses the processes of mining, crushing, and grinding to produce a lithium concentrate. The lithium concentrate is typically roasted before being subjected to acid leaching and crystallization to produce lithium chemicals. A typical lithium yield is around 60-80%, over a few weeks to months. This pricess, however, has a high carbon footprint and high water usage, so it is not the most suitable choice for achieving sustainability.

Sedimentary lithium extraction targets lithium within clays and evaporites that are softer and finer than hard rocks, with lithium more loosely bound to minerals. The lithium extraction follows a similar process to that of hard rock, although the calcination step may be omitted and less crushing and grinding is needed. Sedimentary lithium extraction is not yet commercially proven, and the method requires verification at a large scale to prove its economic and technical viability.

IDTechEx’s latest report, “Direct Lithium Extraction 2025-2035: Technologies, Players, Markets and Forecasts”, offers further details and insights into lithium extraction processes, comparing efficiency, effectiveness, and sustainability. IDTechEx also explores key drivers and challenges within the lithium extraction sector, as well as the main applications for lithium, including references to Li-ion batteries.

For more information, including downloadable sample pages, please visit www.IDTechEx.com/LithiumExtraction.

For the full portfolio of electric vehicle market research available from IDTechEx, please see www.IDTechEx.com/Research/AM.